VHF

Alien N4+ - Dental Milling Machine

Wet grinding reloaded. N4+

The N4+ is a wet processing machine for grinding glass ceramic, composite and zirconium blocks as well as titanium abutments. This machine combines the high precision and fast drives common to all vhf machines with a liquid cooling system in an extremely compact housing.

|

Ideal for the in-office labThe N4+ is ideal for in-office laboratories that want to produce the work without delay and avoid the higher costs associated with external production. With the combination of the wet grinding machine N4+ and a dry milling machine, users can work simultaneously and minimize the cleaning effort that most hybrid machines would require (excluding of course vhf’s R5 with its revolutionary DirectCleanTechnology).

|

|

|

For a variety of indicationsFor crowns and bridges, inlays, onlays, abutments, telescopic crowns, veneers, table tops, etc.

|

|

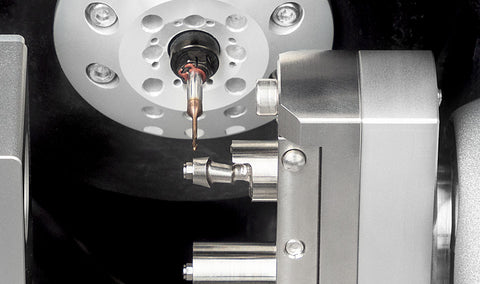

Tool change in no timeThe tool magazine can be inserted quickly and effortlessly with a single movement. The automatic changer offers space for up to 8 tools.

|

Enjoy the freedom of choice.

No material is off limits: blocks, and abutments

Maximum freedom of indication

Further features

Exceptional precision

- Restorations in ultra HD

- Premium spindle with 4-fold hybrid ceramic ball bearings for maximum running smoothness

- 3 microns repetition accuracy

Sophisticated design

- Eight fluid nozzles for even tool cooling

- Highest rotational speeds of up to 80,000 RPM with 800 watts of power

- Heavy industrial quality

Absolute independence

- 38 block materials from 20 manufacturers – and rising

- 1,300+ titanium and CoCr prefabricated abutment blanks from 11 manufacturers

- Ideal for labs and in-office labs

University validated results

- Researchers at University of Washington confirmed exceptional precision of – 10 μm and + 26 μm with milling of titanium custom abutments

Maximum economy

- Work on up to 3 blocks with 45 mm length at the same time

- Automatic changer for 8 tools

- Webcam in working chamber for remote monitoring

- Ethernet interface for stable connection

- Removable coolant tank

- 24-month warranty

- DentalCAM software with DirectMill function – included in scope of delivery and without license fees

Warranty

1 Year limited warranty on all parts, except for wear and tear.

Tools other than OEM VHF Tools will void warranty.

Bundles

Installation

|

No Installation |

|

|

Remote Installation |

|

On Site Installation |

CAM Computer

|

No Computer

|

|

|

Computer with Monitor Includes 27" Monitor, Wireless Keyboard and Mouse Combo. |

Suction Unit

|

No Suction Unit |

|

|

Renfert Silent CompactCAM

Details

|

Alien Zirconia Packages

| 1 of each | STARTER | ESSENTIAL | PRO |

|---|---|---|---|

|

12mm A2 16mm A2 20mm A2 |

12mm A1, A2, A3, B1 16mm A1, A2, A3, B1 12mm A1, A2, A3, B1 |

12mm A1, A2, A3, A3.5, B1, B2, B3, C1, C2, D2, D3, White 16mm A1, A2, A3, A3.5, B1, B2, B3, C1, C2, D2, D3, White 20mm A1, A2, A3, A3.5, B1, B2, B3, C1, C2, D2, D3, White 25mm A1, A2, B1, White 30mm A1, A2, B1, White |

|

12mm A2 18mm A2 |

12mm A1, A2, A3, Hollywood 18mm A1, A2, A3, Hollywood |

12mm A1, A2, A3, A3.5, B2, C2, Hollywood 18mm A1, A2, A3, A3.5, B2, C2, Hollywood |

|

14mm A2 20mm A2 |

14mm A1, A2, A3, B1 20mm A1, A2, A3, B1 |

14mm BL1, BL2, A1, A2, A3, B1 20mm BL1, BL2, A1, A2, A3, B1 |

|

14mm A2 20mm A2 |

14mm A1, A2, A3, B1 20mm A1, A2, A3, B1 |

14mm BL1, BL2, A1, A2, A3, A3.5, B1, B2, C1, C2, D2, D3, White 20mm BL1, BL2, A1, A2, A3, A3.5, B1, B2, C1, C2, D2, D3, White |

OEM VHF Tools

| Tools | |

|---|---|

|

– universal cutters

|

Customize it!

![]()

|

|

![]()

Alien HT Shades |

Alien HT is available in all VITA Classical shades plus white. |

|

Share this Product

QUESTIONS & ANSWERS

Ask a Question-

In the fact sheet you show the N4+ as wet milling. You include a dry suction machine as one of the options. Why would dry suction be needed?

You can still PMMA and Zirconia is block forms.

-

With the N4+, can I use both the blocks from my MCXL mill from Sirona, and discs? Since most of my restorations are single units, is it possible to mill a single restoration from a disc, use a different disc, then replace the original and mill other restorations? Do you also have small zirconia sintering ovens?

The N4+ only uses Blocks, not Discs.

Even if you wanted to fit more than one unit a block, this would not be possible, since the CAM software is different.

We do not sell small zirconia furnaces. -

How quickly can this milling unit cut out a sports mouthguard? We make 20,000+ custom mouthguards per year and we are interested in purchasing a machine to help with cutting.

This machines does not cut Mouthgaurds. What you are lookign for is the VHF E3